Running an e-commerce business means keeping track of many different elements — from managing your inventory and warehouse to ensuring that nothing gets damaged during transit and that the order fulfillment process runs as smoothly as possible. And with so many moving parts, it can be hard to keep up.

That’s why no e-commerce business — not even enterprise-level retailers — is immune to these logistical issues.

Sometimes, these things are out of your company’s control — rising fuel costs and various economic factors are prime examples. Other times, the cause may be human error.

Either way, knowing how to deal with logistical challenges is crucial for ensuring cost efficiency and delivering a best-in-class customer experience.

This article will walk you through the most common logistical issues and how to work through them.

What are logistical issues?

Logistics can be defined as the process of planning, executing, and overseeing the flow of goods across the supply chain efficiently and cost-effectively.

It is a complex process that involves many different “moving parts.” From managing the supply, warehouse infrastructure, and transportation of goods to inventory control and meeting delivery deadlines and consumers’ demands — it all falls under “logistics management.”

The definition of business logistics, provided by the Chartered Institute of Logistics and Transport in the Glossary of Terms and Dictionaries, summarizes the seven Rs of logistics as follows:

“Getting the Right product, in the Right quantity, in the Right condition, at the Right place, at the Right time, to the Right customer, at the Right price.”

In that sense, it can be viewed as the backbone of the supply chain.

Many different aspects have to be carefully managed and synchronized to keep the goods flowing. And that leaves more room for issues to arise at various stages of this process.

And when they do, the effects can be devastating.

Poor logistics management can be costly, affecting the company’s productivity and bottom line, harming the brand’s reputation, and hindering future growth. Moreover, missed deliveries and damaged goods can negatively impact customer satisfaction and loyalty.

By opting for DeliverySolutions as your third-party logistics provider, you’ll gain access to our Omnichannel Experience Management (OXM) Platform. This comprehensive supply chain management solution makes it easier to meet those seven Rs of logistics.

One example of a company that’s felt the consequences of poor logistics management we’ve seen in recent history is Toys R Us.

As you may know, after being in business for seven decades, the company filed for bankruptcy in September 2018, closing 735 of its stores throughout the US.

However, the logistics issues we’re referring to here took place two decades earlier:

Around 1998, large brick-and-mortar retailers began offering online shopping, enabling consumers to purchase goods through their e-commerce sites. In time for the holiday season, the international toy retailer joined others in 1999, promoting its online store’s ability to fulfill all orders placed by December 10.

Unfortunately, as it turned out, the retailer was grossly unprepared for the influx of orders placed through the e-commerce site.

A lower inventory level didn’t cause these delivery delays — it was the logistics of preparing and shipping these orders out fast enough.

1. Rising fuel and fleet maintenance costs

The surge in fuel and fleet maintenance costs is a major challenge in e-commerce logistics. These mounting recurring expenses can significantly impact supply chain dynamics.

A higher fuel energy index directly translates to elevated transportation costs, affecting overall operational expenses. These fluctuations directly impact inventory management, transport costs, and warehousing expenses.

While slight drops in logistics costs have been noted in recent months, these nuances reflect the intricate interplay of economic forces and the evolving landscape of e-commerce logistics.

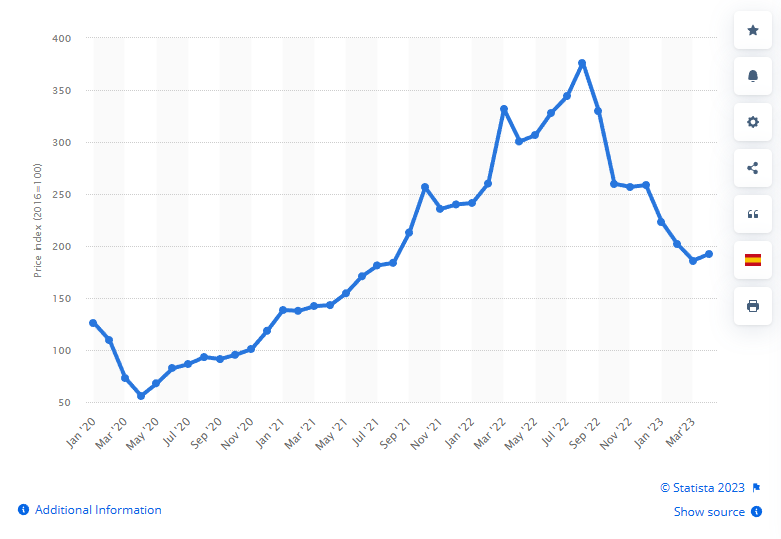

The global fuel energy price index exemplifies this trend:

From a base of 100 in 2016, the index surged to 192.37 index points by April 2023.

The upward trajectory, which saw a six-fold increase between 2020 and 2022, stemmed from diverse factors, including energy supply shortages and geopolitical tensions, notably exacerbated by the Russia-Ukraine conflict.

Economic factors, marked by fluctuations in the fuel energy index, directly influence the cost structure of logistics operations, which, in turn, impacts profitability and pricing strategies, potentially trickling down to consumers.

Another concern here is rising vehicle maintenance costs. While the American Trucking Associations’ Technology & Maintenance Council reported that, by the end of 2022, the increase in maintenance costs has slowed down — but it remains high, nonetheless.

The surging costs of container shipping further exemplify these complexities:

Shipping container expenses witnessed unprecedented spikes, with costs for a 40-foot container soaring to over $11,000, a dramatic rise from the pre-pandemic figure of $1,300.

Navigating the unsteady tide of various economic factors demands proactive strategies. Your company needs to carefully balance pricing strategies and delivery path optimization and invest in fuel-efficient technologies to mitigate the impact of these challenges.

2. Lack of skilled labor

Another challenge that a logistics business may face is the need for more skilled labor. There’s a serious labor shortage within the transportation and logistics industry.

The importance of skilled labor in the logistics business cannot be understated. Every link in the supply chain relies on trained personnel to guarantee smooth operations, timely deliveries, and efficient coordination. Without an experienced workforce and team, the logistics process seriously risks derailment, delays, and dissatisfied clients.

There’s no shortage of job openings, though. This discrepancy has created an alarming disconnect between demand and supply, highlighting an ongoing issue that demands immediate attention.

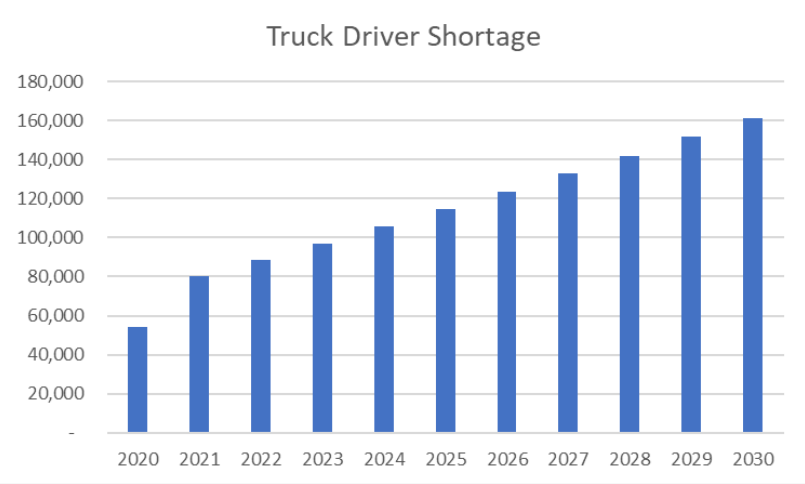

There are simply no workers available to fill them; demand has long surpassed supply:

In 2021, the American Trucking Associations estimated that the shortage of truck drivers would reach a historic high of more than 80,000. The forecast also stated that if trends continue, we’ll see that number go up to 160,000 by 2030.

It is with 100% certainty that we say that the lack of skilled labor extends beyond individual businesses to the entire logistics ecosystem. These professionals are the linchpin that make sure goods are efficiently transported from point A to point B, that inventories are managed effectively, and that deliveries are executed seamlessly.

Only by filling this gap can the logistics sector maintain its pivotal role in the global economy, securing the fluid movement of goods and client satisfaction worldwide.

Proactive measures are essential for cultivating a skilled and proficient labor force — ensuring the stability and efficacy of the logistics industry.

3. Challenges of managing complex systems

The highly fragmented nature of the logistics sector and the fact that it requires managing complex systems poses one of the most significant logistical issues to date.

With multiple steps and several different teams involved in completing each order, it can be hard to keep track of things and ensure everything goes off without a hitch.

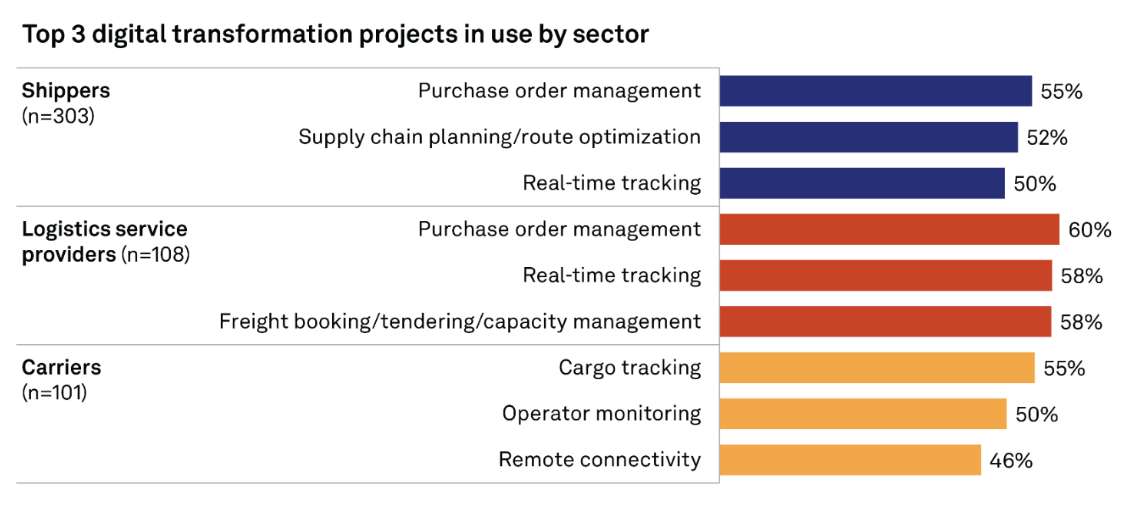

According to the Supply Chain Digital Transformation Enterprise Survey conducted in 2023 by S&P Global Market Intelligence, 67% of organizations in the shipping and logistics industry report having a digital transformation strategy in place. Moreover, nearly 31% report that they’re currently considering digital transformation plans.

Digital transformation is definitely top-of-mind for the logistics sector — even if it’s often perceived as a technology laggard.

Another survey conducted by Gartner has revealed that as much as 82% of CEOs working within the supply chain industry will prioritize investing in digital capabilities at all levels of their enterprise. That, of course, includes the implementation of supply chain technologies.

These findings should come as no surprise. Digital transformation within supply chain management has been shown to have a positive impact on mitigating risks, cutting transportation costs, and increasing efficiency and productivity. And, ultimately, improving customer satisfaction.

The sheer complexity of these processes, coupled with a lack of standardization, integration, and data management, has proven to be a huge obstacle when streamlining operations, let alone integrating new technologies into existing systems.

That’s where third-party logistics providers come in; DeliverySolutions’ OXM enables you to tie all these different components into a unified, omnichannel experience.

4. In-transit damage and failed deliveries

Regarding delivery and logistics, the challenges of in-transit damage and failed deliveries are pivotal concerns.

The last-mile delivery segment encapsulates the final and often delicate stage of getting your products to consumers. Late or incorrect deliveries — and the potential for goods to sustain damage during transit — directly impact customer satisfaction and operational efficiency.

Addressing these issues preserves brand reputation and customer loyalty and optimizes last-mile logistics. Navigating the intricacies of timely, accurate, and damage-free deliveries underscores the vital role these aspects play in ensuring the success of the entire delivery ecosystem.

Businesses are capitalizing on the surge in online sales, with a significant 69% reporting an uptick in their average online order values due to the pandemic. Additionally, according to information pulled from the report, 54% of enterprises witnessed an upswing in international orders in the last year.

Meanwhile, consumers also engage in overseas purchases, with 45% confirming cross-border transactions. Despite this, 55% of e-commerce customers acknowledge the likelihood of delivery delays for international orders.

Furthermore, 71% of businesses concur that inaccurate delivery details are a primary reason behind delivery failures. That’s especially relevant, given common issues like incorrect address entries.

An equivalent proportion of businesses recognize that customers might underestimate the impact of mistyped addresses on delivery success.

In such scenarios, address verification emerges as a crucial safeguard.

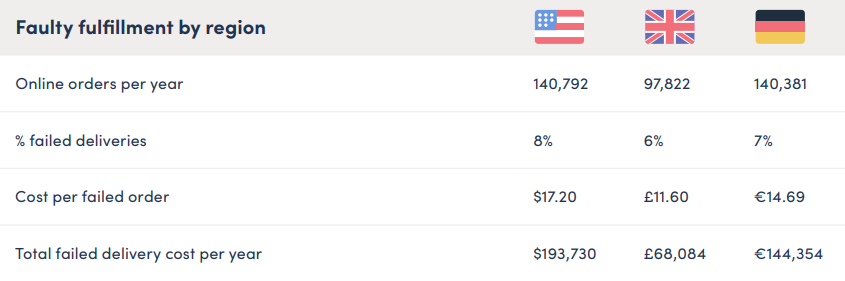

Delayed, incorrect, and otherwise failed deliveries can cost the company an average of $17.20 per failed order.

Common issues like tardiness or incorrect shipments and the vulnerability of products underscore the importance of precision.

Providing seamless, timely, and reliable deliveries not only cultivates customer trust and loyalty but also optimizes the efficiency of last-mile operations — ultimately shaping the success and reputation of the entire delivery ecosystem.

5. Managing customer expectations

Using online shopping and same-day delivery, customers have come to expect instant gratification, putting logistics companies under immense pressure to keep up with the ever-increasing demand.

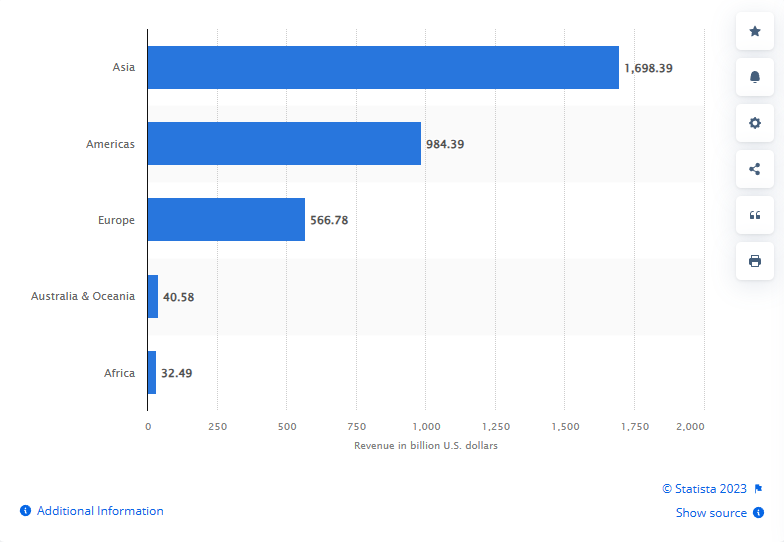

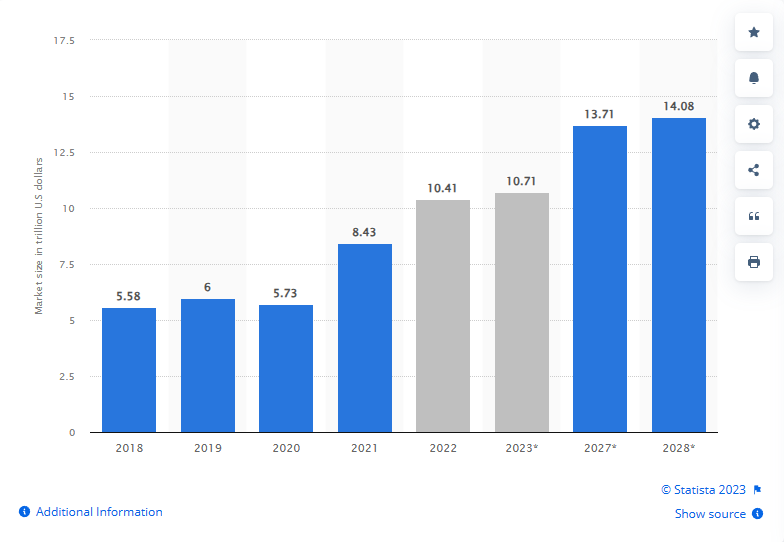

Retail e-commerce revenue in the US alone reached 1T USD in 2022, which speaks volumes about consumers’ habits and the shift to online shopping:

Supply chain managers might be aware of the complexity of overseeing logistics systems — but their customers likely aren’t.

They don’t see what goes on behind the scenes. The tactical decisions and the challenges of managing distribution centers, inventory control, delivery path optimization for dozens of vehicles, or disruptions in the supply chain — it all means very little to them.

What they expect is fast delivery of the goods they’ve purchased online. Two-day delivery is the norm.

And according to recent stats, a growing number of consumers — as much as 41% — now expect to receive their packages within 24 hours of placing an order online. Furthermore, 24% of global shoppers would prefer their packages to be delivered within two hours.

The deadlines are tight — and it can be hard to meet these expectations. However, considering that customer service levels are one of the key competitive differentiators, it must be done.

A 2021 survey further supports these claims, with 44.5% of executives worldwide revealing that they consider customer experience a primary competitive differentiator for their company.

Adopting strategies to help logistics companies speed up the delivery process, adapt to ever-changing consumer trends, and deliver a satisfactory experience is imperative.

Conclusion

The order fulfillment process is complex, with multiple components to manage at each stage. Any disruption to these components can significantly impact the overall process.

Rising fuel and maintenance costs, lack of skilled labor, challenges of managing complex systems, in-transit damage, failed deliveries, and the pressure of managing customer expectations are all issues that can occur at various stages and hinder your transport.

While you can’t avoid logistical issues altogether, being proactive and embracing digital transformation can reduce the risks and help you overcome problems as they arise.

If you want to optimize your order fulfillment process and deliver a better customer experience, speak with an expert from DeliverySolutions today and schedule a personalized demo to see why we are your most reliable solution.

With an impressive 18 years of experience in the SaaS industry, Justin Corbell stands as our accomplished Vice President of Sales. A proud LSU alumnus, Justin’s journey is marked by pivotal roles at industry giants, including ReachLocal (now LocaliQ under Gannett Co), BigCommerce, and Scandit. Originating from Little Rock, AR, his interests encompass golf, tennis, and skiing, revealing a well-rounded nature. Whether basking on a beach or conquering mountain slopes, Justin finds solace in diverse vacation spots. His expertise is underpinned by his commitment to constantly evolving and keeping pace with industry trends and shifts. Justin’s leadership and vast experience drive Delivery Solutions’ efforts to new heights.

(

( (

(