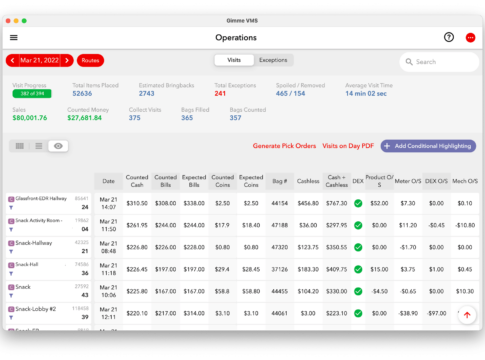

Gimme, whose technology helps food service and grocery store delivery operators automate merchandising has announced several new warehouse and inventory management features for its flagship VMS platform. These significantly improve warehouse inventory management and solve product shortages—all in a simple and easy-to-use ecosystem.

Recognizing the unique challenges of today’s warehouse leaders, Gimme made significant investments in its all-in-one platform to improve warehouse accuracy and solve product shortages. The platform update includes new tools for improving warehouse fundamentals and three new significant features to help solve product shortages and inform warehouse rationing. These changes will improve order accuracy while increasing warehouse logistics visibility, making operations more efficient and effective.

“Accurate warehouse data helps teams make better decisions, and Gimme’s latest features empower decision-makers like never before,” said Cory Hewett, Co-Founder and CEO of Gimme. “Being shorted products at the warehouse level are the headwinds that frustrate our customers and put revenue at risk. Markets have now become the biggest drivers of revenue. This update not only provides our customers with critical data, it also actively suggests the right answers to confidently handle product shortages.”

In addition to the new fundamental tools, Gimme’s latest release includes three new notable additions to the platform that profoundly improve inventory management, including:

Warehouse Rationing

Gimme detects if you will run out of a product before the next delivery, then provides options to intelligently redistribute remaining inventory to reduce the probability of a stock-out in your markets and machines.

AutoPar

The new AutoPar feature helps customers visualize the ideal number of products differently. Instead of using a static warehouse par, AutoPar intelligently calculates warehouse product data based upon user-defined duration of days.

Suggested Order Quantity

This feature, unique to Gimme’s platform, uses intuitive, days-based AutoPar calculations, along with real-time on-hand inventory and the estimated delivery date of the next order to automatically calculate the number of each product to order. This improved process and user interface make it easier to identify mistakes and make edits prior to ordering. If suggested quantities are ordered, it also lowers the probability of future stock-outs.

In addition, Gimme VMS implements AI and computer vision to increase sales from optimized merchandising at the point of sale and reduce stock-outs, bringing unprecedented efficiency as a mobile-first application for iOS devices.

“Whether accounting for supply chain disruptions or seasonal ordering habits, inventory management is always in flux, requiring accurate data and actionable insights to maintain optimal stock,” explains Jared Mooring, the purchasing and inventory manager at M&M Sales Company. “These changes in Gimme VMS couldn’t be more timely or relevant for a food service operator today.”

Notably, Gimme VMS is device agnostic, with native apps for smartphones and tablets, as well as native support for Windows PC. It also works with telemeters and Gimme Key Pros to process information in real time. Gimme VMS uses live field data to provide greater accuracy and control over product inventory in multiple warehouses and ensures stable operation when offline.

Recognizing that inventory management is just one component of effective warehouse management, Gimme is developing an AI-powered schedule suggestion tool to optimize labor distribution and alleviate scheduling concerns. This extends the company’s capacity to help warehouse leaders address shortages by enhancing their capacity to navigate staffing shortages and allocate human capital appropriately.