Ecommerce, international markets, and evolving customer expectations mean that more and more businesses are aware of just how complex transportation logistics can be.

Between the digital revolution and the COVID-19 pandemic, ecommerce has exploded in popularity. Just over half of consumers do more of their shopping online now than they did before the Covid-19 pandemic, and 29% say they now do ALL of their shopping online.

With online shopping comes home delivery, and many brands are learning how to navigate this process. Since the last mile of the shipping process has unique challenges, businesses must reckon with last mile logistics.

In this article, we’ll explain what last mile logistics are, the most common types of logistical challenges, and how businesses are solving those challenges.

What is the last mile in logistics?

Logistics are how businesses get things done. It refers to how a company handles the process of getting products to customers.

Logistics includes:

- Warehousing

- Fleet management

- Transporting materials

- Order fulfillment

- Customer delivery

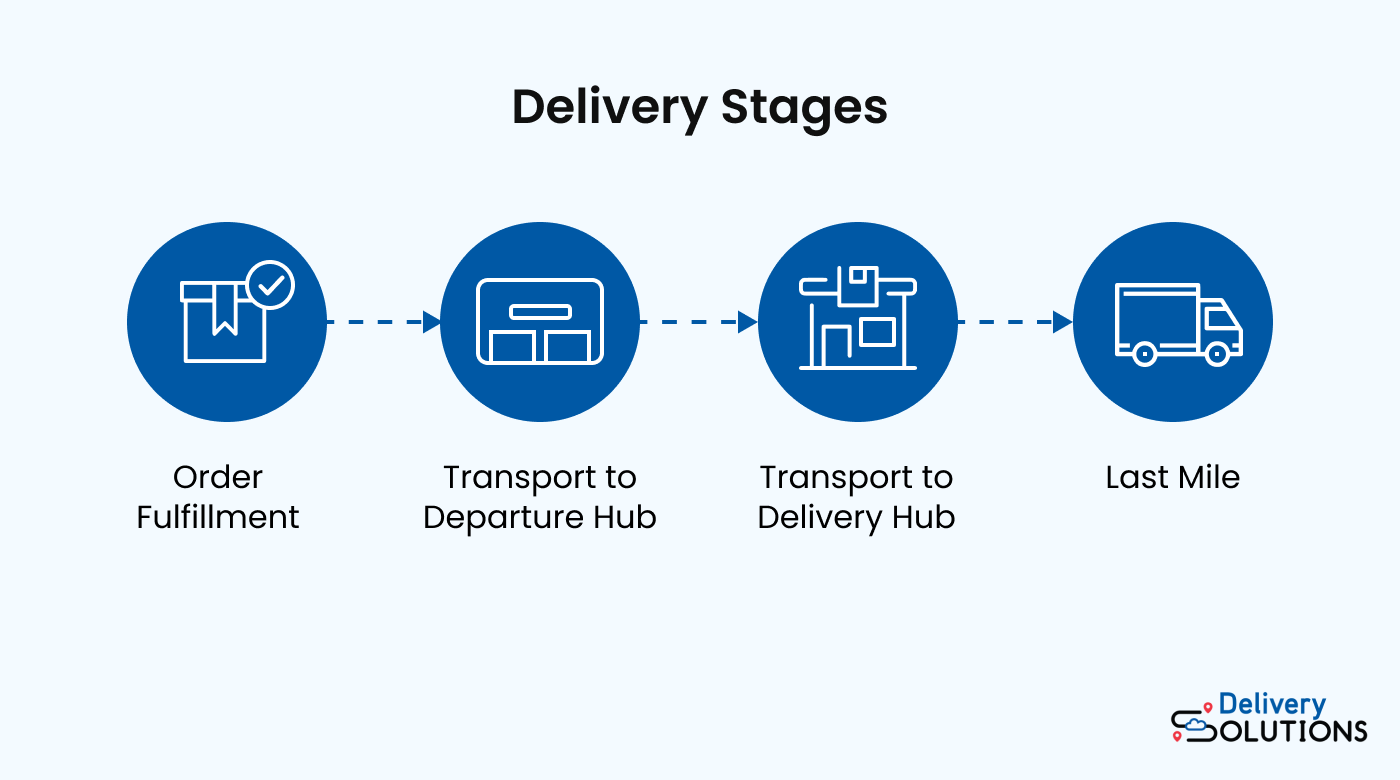

While logistics often begins with acquiring the raw materials, last mile logistics refers to what happens during the “last mile” of delivery. The “last mile” is the final stage in the delivery process, where an order moves from a local shipping hub to its final destination. Whether that portion of the journey is a half mile or 25 miles, this final stage is typically called the “last mile.”

Last mile logistics, therefore, are the logistical processes involved in the last mile phase of the delivery.

Last mile logistics example

To get a sense of what last mile logistics are, we can look at an example.

A user places an order from an ecommerce site. The business then has to perform the practical work and planning required for the delivery. That includes fulfilling and packaging the order in their warehouse, batching the order for shipment, and coordinating pickup by a delivery provider. The delivery provider then batches a shipment to the customer’s nearest shipping hub.

Finally, the order must travel from the shipping hub to its final delivery destination. It has reached the last mile, but there are still important logistical considerations in this step, such as whether the order has been transferred from a long-distance shipping provider to one that specializes in last mile delivery.

Other last mile logistics questions include the following:

- How will this package be batched with orders in the same neighborhood?

- Which delivery driver will transport the order, and what route will they take?

- Will the customer receive an accurate estimated delivery time? How will that be communicated?

- Does the order require a customer signature, or can the order be left on the customer’s doorstep?

The last mile of the shipping process comes with specific challenges that both the ecommerce site and the shipping provider(s) want to solve.

Why is last mile logistics so important?

The last mile is the stage of shipping that the customer most directly interacts with. When and how their purchase is delivered is a key part of the customer’s overall experience of the product. If their order is delivered to the wrong address or poorly handled, it could be damaged or lost.

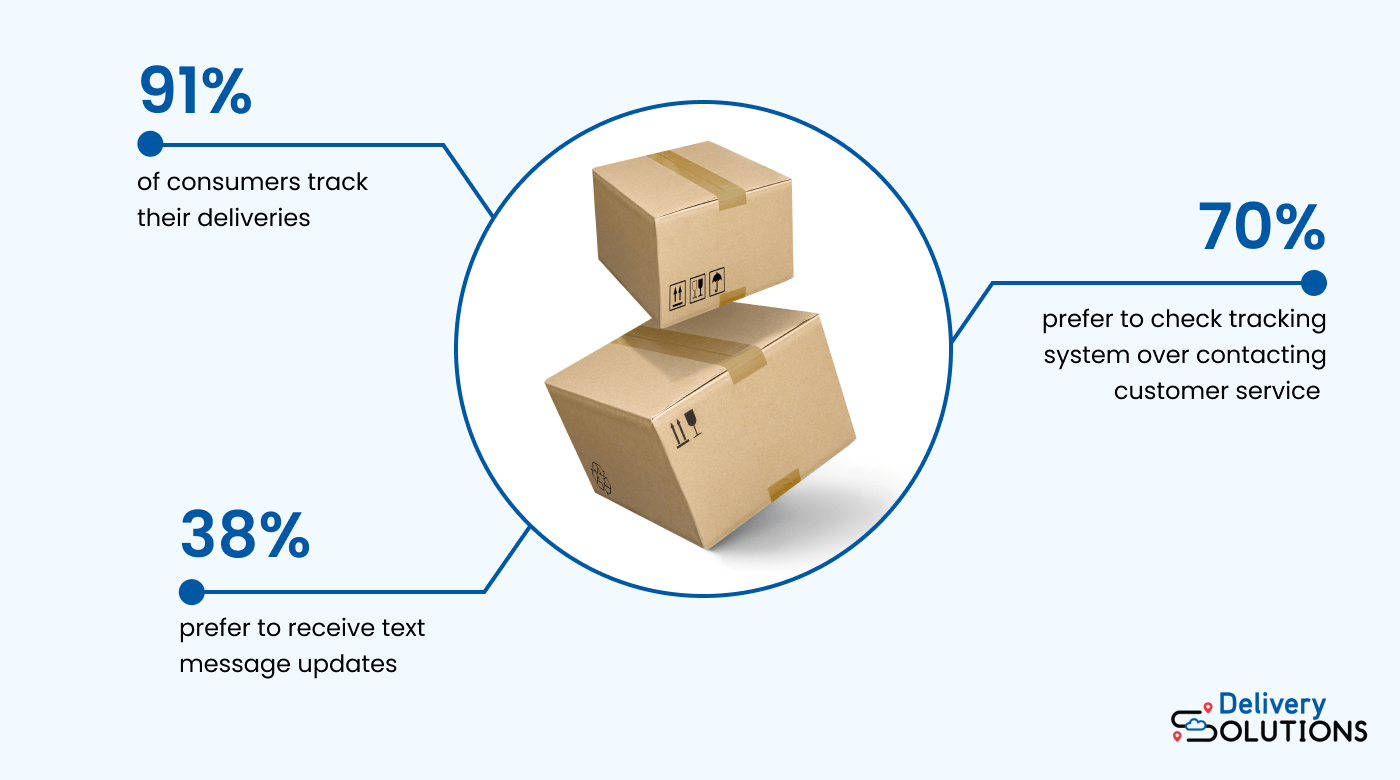

Even if the customer receives the order, they expect timely communication. Nine in ten people actively track their online purchases during the delivery process. More than half (69.7%) of customers said that if their orders were delayed and they weren’t notified, they’d be less likely to shop with the same retailer again.

Consumer expectations are only getting higher.

The ecommerce industry gained 10 years’ worth of ground in just three months due to the COVID-19 pandemic. Ecommerce giants like Amazon have made online shopping and delivery more common. Their ability to provide fast and free shipping is a huge advantage.

Today, 80% of online shoppers expect free shipping above a certain purchase amount. Then there’s the 66% of surveyed shoppers who say they expect free delivery on ALL orders. Last mile logistics make it more difficult to meet these expectations.

Cost of last mile logistics

Last mile transport is notoriously more expensive than other stages of delivery due to its complexity and the individualized attention needed for packages for delivery. This is why businesses are always looking for solutions to the last mile delivery problem.

The last mile is less efficient and more expensive than the other delivery stages because most orders are dropped off one by one, requiring more mileage and higher labor costs. Multiple customers mean more stops are required, which takes more time, fuel, and human labor.

Instead of a plane or truck taking hundreds of orders from Shipping Hub A to Shipping Hub B, you have a smaller truck stopping at dozens of addresses, where the driver must safely park or idle, find the dropoff point, and then return to do it again (and again and again).

With more customers expecting free delivery, businesses are caught between providing a great customer experience and minimizing delivery costs. That’s why last mile logistics are so important — they keep your shipping costs under control.

Last mile logistics challenges

In this phase of logistics, the challenges fall into a few main categories. Here we cover the most common types of logistical challenges and how brands are innovating and solving them.

Navigation

Labor and fuel are two of the biggest costs related to last mile delivery. Efficient navigation and routing are important for both. The right navigation and routing tools allow drivers to deliver more packages, as they spend less time in traffic and can optimize the order in which the deliveries will be made.

Businesses and delivery service providers are relying more and more on routing software and tools using real-time traffic information and artificial intelligence. The average human supervisor might not be able to plan a route optimized for delivery windows, driver schedules, and traffic patterns. Routing tools, however, can incorporate all of these factors to save time and fuel.

Shipping capacity

The explosive growth of online shopping and home delivery is stretching the shipping industry to its limit. The explosion in ecommerce has drastically outpaced the growth of shipping capacity. In fact, an estimated 400,000 trucks have recently been taken off the road. Even major brands, like Nike and Gap, have dealt with shipping restrictions due to capacity issues.

One way that retailers are combatting the capacity problem is by turning to gig economy workers, such as rideshare drivers. By tapping into rideshare drivers and other on-demand labor, companies are finding new ways to manage the growing demand for delivery. Target, for example, uses Shipt for same-day delivery on groceries and other goods.

Speed

Delivery speed is important for acquiring and retaining customers. Major retailers, like Amazon, have made fast delivery a big selling point and list estimated delivery dates (EDDs) right next to product prices.

One survey found that putting the EDD on a product page positively influences 75.1% of shoppers’ purchase decisions. Just like product details and price, EDD has become a key part of online shoppers’ decision-making.

And delivery speed also impacts decision-making after the fact. After two or three late deliveries, 65% of consumers say they will stop shopping with a brand. A survey found that, along with damaged items and incorrect orders, late delivery was a leading reason for returns for 21% of consumers.

With so much riding on delivery speed, brands are incorporating old and new strategies. One strategy that’s been used for decades is batch processing, where the retailer or shipping provider combines similar orders or delivery destinations for faster processing. Drone technology, on the other hand, is new, and brands like UPS and CVS are turning to it for fast and safe delivery.

Skilled assembly and unpacking

COVID and the acceleration of online shopping have affected much more than how people buy groceries and clothes. Of global consumers, 26% said they are more willing to buy appliances online. Many major appliances require skilled assembly, and some consumers need home assembly for furniture, exercise equipment, and electronics.

For retailers whose products require skilled assembly or home installation, that means securing the necessary labor as well as coordinating with customers. Brands that sell air conditioning units, for example, need someone who knows how to properly install vacuum pumps and other equipment, and they also need the customer to be home during the delivery.

For some retailers, this means employing your own installation professionals, while others may partner with contractors. The growth of online shopping for major appliances and furniture has also led to services like TaskRabbit, where customers can hire help with assembly.

Tracking and communications

Today’s customer wants to know where their order is at all times. And expectations have progressed beyond a “your order has shipped” notification and estimated delivery date.

With apps like Uber and DoorDash, customers are now accustomed to getting real-time updates and even driver-tracking access.

While email is the go-to platform for order confirmations and receipts, the increased interest in tracking comes with more customers (38%) preferring text notifications. This level of transparency requires cooperation between shippers and retailers. Some businesses partner with major shipping outlets like UPS and rely on their tracking system to inform customers.

With Delivery Solutions, retailers can provide a transparent tracking experience without limiting their shipping options. This allows businesses to take advantage of the full range of delivery innovations without sacrificing the continuous tracking capabilities that customers now expect.

Proof of delivery

Proof of delivery (POD) is just what it sounds like: a record showing that an order has been delivered to the recipient. Proof of delivery is important because it prevents disputes from occurring between retailers, shippers, and customers.

The traditional procedure for proof of delivery is for the delivery driver to obtain the customer’s signature on paper. But many shipping providers have moved to digital systems, called electronic proof of delivery (EPOD).

In a customer’s absence, some shipping providers have made it standard practice for delivery drivers to take a picture of the item at its destination. Electronic signatures and pictures make it easier for shippers and retailers to maintain accurate delivery records.

Innovations in last mile logistics

The underlying challenges of last mile logistics are complex, involving supply chain management, different kinds of labor, and coordination between retailers, shippers, and customers. Traditional delivery service providers and startups alike are turning to new technology and approaches to delivery operations.

In terms of technology, brands continue to experiment with drones and other autonomous vehicles. Domino’s, for example, has partnered with Nuro to implement self-driving delivery vehicles in Houston. Smaller delivery robots by Refraction AI aim to minimize both delivery time and cost.

Collection lockers, on the other hand, pass on many of the last mile’s challenges to the customer. By enabling customers in walkable urban areas to collect their orders at convenience stores or other locations, Amazon is reframing the online shopping experience.

While delivery lockers and autonomous vehicles are unlikely to completely replace drivers and other labor, they could help ease the strain caused by increased delivery expectations.

Delivery Solutions for last mile logistics

The last mile is an important stage of the delivery process.

Businesses, big and small, are hustling to find efficient and affordable ways to fulfill orders. When you understand the greatest challenges to last mile logistics, you can better evaluate the available solutions.

Having access to the full spectrum of shipping providers and tools makes your business better able to create a great customer experience. That’s why brands are choosing Delivery Solutions to optimize their last mile delivery operations.

Schedule a demo to see how Delivery Solutions can give your business the tools to manage last mile logistics.

The Omnichannel Experience Management (OXM) Platform by Delivery Solutions orchestrates fulfillment experiences for enterprise retailers, supplying flexible optionality for consumers and priming merchants for innovation at scale.

Tyler Cruver brings 8 years of dynamic expertise in business development to our team. A proud alumnus of Bryan College, Tyler’s journey in the field has been enriched by his past roles at Protection 1 and CPI Security. Hailing from Dayton, TN, he’s a nature enthusiast who finds solace in hiking and soccer. Tyler’s passion for exploring new horizons is evident in his love for traveling, with Rome, Italy being his top vacation destination. Guided by his belief in active listening, Tyler’s business philosophy echoes, “You have two ears and one mouth, so listen twice as much as you speak.” When he’s not forging valuable B2B relationships, you might find him savoring his favorite food, tacos de pastor, and indulging in a refreshing agua de jamaica. Tyler’s blend of experience and perspective makes him an invaluable asset to our sales and marketing endeavors.

(

(